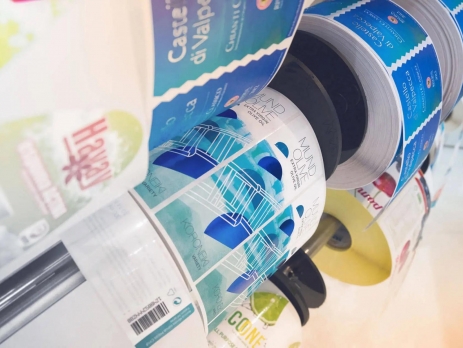

Whether for marketing or legal reasons, all products need a label or a packaging. Whether to identify the brand, the producer or the distributor, provide the consumer with relevant information regarding on how to consume, transport, conserve and recycle the product, etc. Even products that were formerly marketed in an undifferentiated way (such as fruit) today are often labeled to identify the producer and its origin.

In this article we will cover some of the labeling solutions that the market offers. These are specific solutions that must be considered depending on the type of product (food, non-food, frozen, fresh, etc) and also on the way in which the product is intended to be positioned on the market.

Thermal labels

Suited for short-term applications such as travel, logistics, retail, receipt printing, etc., these labels have a special coating that makes them heat-sensitive, which is why they do not need ribbons as the printing is done on thermal transfer printers.

This type of label is normally available for all types of thermal printers and for printers/applicators and scales with built-in printers.

Thermal labels always guarantee adequate optical reading of bar codes and other informative and distinctive elements of the products, and a specific glue is used for each type of product.

Matte labels

Compared to semi-gloss or gloss paper labels, matte (non-gloss) labels guarantee a longer lasting impression and this is the main reason why they are commonly chosen, that is, when the main objective of labeling is durability. However, on matte labels, the print quality and contrast are inferior compared to semi-gloss or gloss paper. Therefore, it is the customer who will have to consider the advantages and disadvantages of each of these alternatives.

Matte labels allow for great print durability, great paper resistance to slightly humid environments and temperature variations, excellent adhesion on a wide variety of materials and, last but not least, they´re certified for direct contact with food.

Semi-gloss labels

Semi-gloss labels are an intermediate solution between matte labels and gloss labels.

Semi-gloss is a finish that gives the label a more appealing image and, compared to matte paper, the print quality is superior. However, these labels are less durable than matte labels. Despite their inferior durability, semi-gloss labels also guarantee good resistance to slightly humid environments and to thermal variations.

The adhesive (glue) of half-gloss labels provides excellent adhesion to many types of surfaces or materials.

High-gloss labels

High-gloss labels are the ideal solution when the objective is to give a very glossy finish to the label. The high-gloss solution guarantees a great print quality and a very shiny effect that may help the product stand out on the stores shelves.

Again, the choice between matte, semi-gloss or high-gloss is a customer decision based on what they want for their label.

Labels made of special papers for oenology

Appropriate for the production of wine, liqueur and spirits labels, these papers usually have a higher quality and grammage, as well as different effects and textures.

Depending on how one intends to position a given brand or product in the market, the use of this type of paper can play a very important role due to the added value that it effectively brings to the final result either visually and also in what concerns the consumers shopping and consumption experience.

Labels on metallic papers

Metallic papers are often used in labels that require a distinctive and impactful look as these papers give a remarkable shine and impeccable finish.

As the label plays a decisive role in the positioning and differentiating process of a brand / product, this type of paper, given its characteristics, can make a real contribution in this process.

White polypropylene labels

White polypropylene labels are normally used to label products for which a more visually appealing image is desired, as they allow a remarkable color printing quality. Furthermore, they are also suitable for labeling chemical products as plastic (PP), compared to paper, guarantees greater readability and durability as it prevents labels from tearing or deteriorating when in contact with certain chemical compounds, fats, oils or moisture.

Furthermore, the fact that they withstand low temperatures, are recyclable and non-toxic makes them widely used in the food, pharmaceutical, healthcare and cosmetic industries.

Transparent polypropylene labels

Transparent polypropylene labels are normally used to label products for which a more visually appealing image is desired, as they allow a remarkable color printing quality. Furthermore, they are also suitable for labeling chemical products as plastic (PP), compared to paper, guarantees greater readability and durability as it prevents tags / labels from tearing or deteriorating when in contact with certain chemical compounds, fats, oils or moisture.

Besides that, the fact that they withstand low temperatures, are recyclable and non-toxic (no toxins) makes them widely used in the food, pharmaceutical, hospital and cosmetic industries.

Metallic Polypropylene Labels

Metallic polypropylene adhesive labels are the most used in the world, especially in packaging, product labels and in industry, replacing other thermoplastics.

These very low elasticity labels, are very resistant to water, tear and temperature as they withstand up to 80ºCelsius, being ideal for products that will be exposed to humid and/or harmful environments.

Compared to other types, metallic PP labels allow the composition of printed packages, which helps in the identification and aesthetic differentiation of the product.

VOID security labels

VOID security labels allow detecting whether the user has manipulated a given product since when removed the label no longer recovers its original appearance and, furthermore, the word VOID is shown on the labels adhesive, proving that there was a deliberate attempt to manipulate/open the product or package.

Although commonly used in technological products (computers, consoles, televisions, etc.) this type of security label can be applied to any other type of product as a form of non-handling assurance.

Destructible Security Labels

These labels are used to identify and seal products that imply warranty and need for identification.

Due to the high adhesiveness of its glue, when there is an attempt to remove the label, it gets destroyed, thus evidencing the attempt to violate the packaging or product.

Destructible security labels feature high resistance to ultraviolet (UV) rays and offer excellent adhesion to many different types of surfaces.

Valéron tags

Due to their durability and resistance to contact with chemicals and natural elements (outdoors, low temperatures, humidity, ultraviolet rays, etc), Valéron tags are particularly suitable for use in outdoor environments, although they can also be used indoors.

Typically, Valéron tags are used for identifying or tracing animals/cattle and for labeling pots and plants.

You have certainly seen this type of tag on pieces of ham, on fish in the fish market and also on garden plants, as non-adhesive tags printed in various colors and shapes to draw attention.

Technical advice

When choosing the most suitable label for your product, feel free to contact us as we will help you in this process which, as you had the opportunity to read, is far more complex than it seems because there are many different solutions available on the market so it is essential that you choose wisely the type of label that better suits your needs.